Factory Sourcing

Around 90% of our sourcing is made through relationships “Guanxi”. Like everywhere, being referred opens up other types of doors. Since 2006 our Hong Kong company StreamTease International Ltd. worked with 750 factories, 350 customers in 60 countries and built a strong network of manufacturers of all types, it is the facto the entity bringing the sourcing expertise to the operations.

Starting from April 1st, 2020, things are somewhat changing for the better, the new regulations announced by the MOFCOM (Ministry of Commerce) make it stricter and a few dozen medical State-owned Enterprise (国企 GuoQi) have been appointed to take full control over the 5 products category: Masks, Temperatures, Coverall, Test kits, Ventilators.

As such, it becomes their responsibility to hand-pick the factories that have the appropriate quality and compliance level according to the buyers’ needs.

This is an effort from the Chinese Government to control the quality of the entire supply chain.

Strong with Class I, II, III medical licenses and years in the field Gigsign Corporation immediately gained close partnerships with quite several GuoQis allowing the trade. In this emergency crisis situation, the key is the rapidity of maneuvering and making it through production lines.

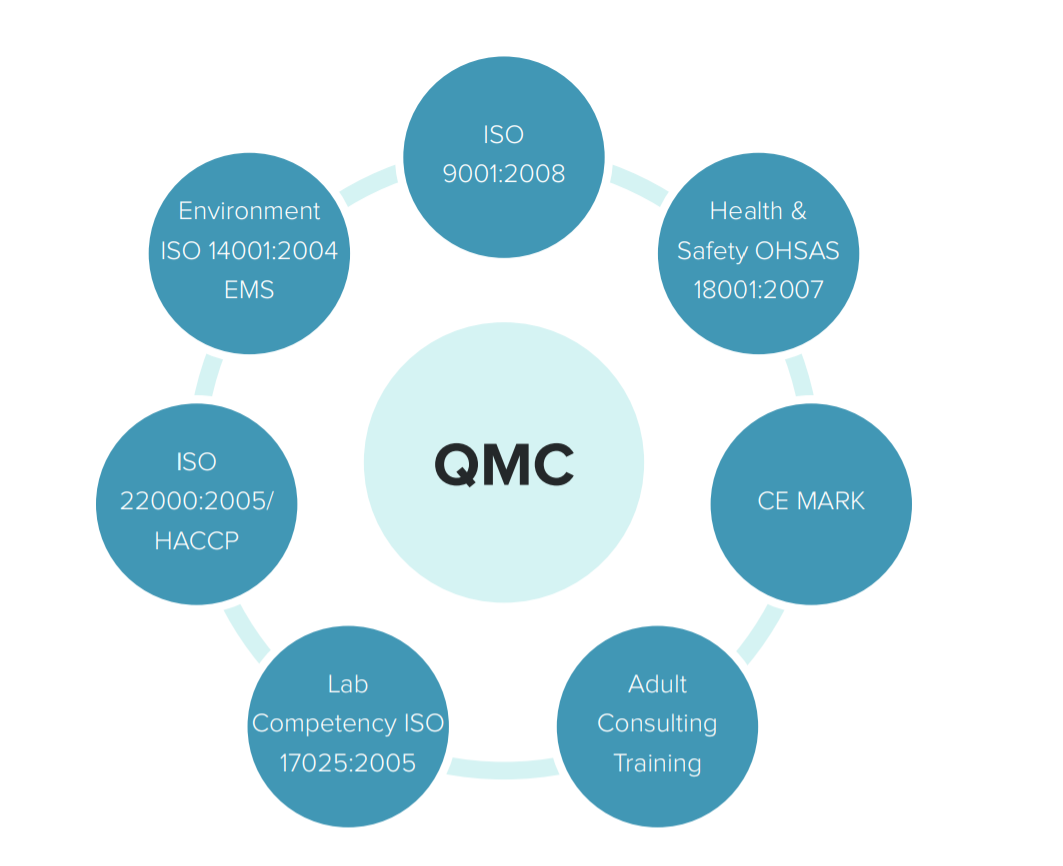

Quality Control

A major part of Gigsign offering is the quality control, that usually lies on a 3-steps routine:

1

A Pre-Production Inspection (PPI) is the next step after the identification and evaluation of your vendor/ factory. It allows you to identify quality risks before manufacturing commences and is an integral part of your risk assessment and quality assurance management

2

DUPRO usually occurs when between 10 to 60% of your product is manufactured and packing for export has begun. It forms part of your overall quality assurance program and provides the opportunity for implementation of the necessary corrective actions at an early stage.

3

Pre-Shipment Inspection (PSI) is an essential element of supply chain management. This inspection takes place at the end of the production process when 100% of the goods are manufactured and packed for export. Container Loading Supervision provides reassurance that your finished goods are handled correctly when loaded into containers to ensure safe transportation and delivery to their final destination in a satisfactory condition.

END-TO-END LOGISTICS

Navigation of Chinese Customs

Since April 10th 2020 new regulations in China are making it cumbersome to navigate in the export process and get customs clear:Not only a specific CI & PL with proper product name designation but also Business license, Medical device production license, Medical device registration certificate, Product inspection report, Product manual, Product certificate, Pictures of products/outer carton and Statement of export of medical materials are needed.

Miss one and you get stuck on the tarmac!

OUR PLANES

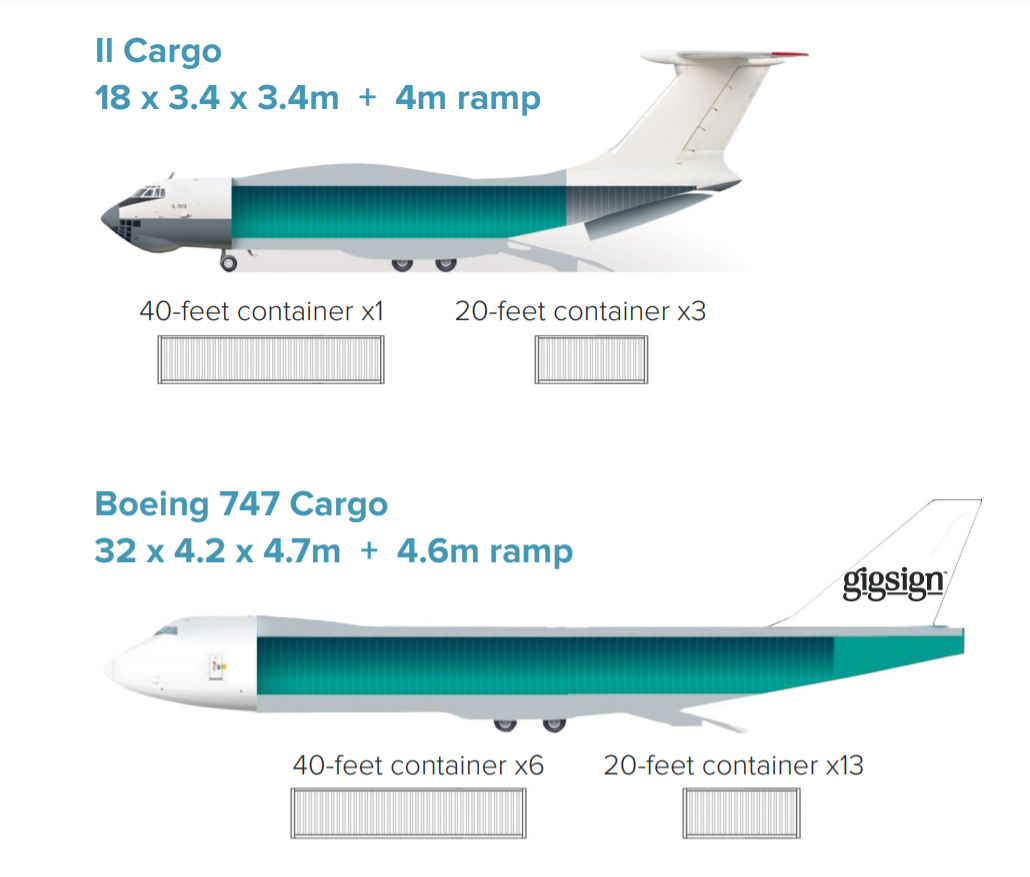

For shipping, Gigsign Corporation works with freight forwarders for partial/consolidated shipments but also works directly with aircraft owners to haul full cargo for largerorders.

Gigsign aircraft fleet comprises of:1 x Ilyushin Il-762 x Boeing 7471 x Antanov AN-124

© Copyright Gigsign Corporation. All Rights Reserved